Case 1

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Remedial (see also Remedial)

Replace the deteriorated sealants

The sealant joints in these areas should be inspected.

If the sealant is missing, a full bead of high-quality, permanently elastic sealant compound should be placed in the open joints. If a sealant material was installed, but has torn, deteriorated or lost elasticity, it should be carefully cut out.

The opening should be clean of all old sealant material.

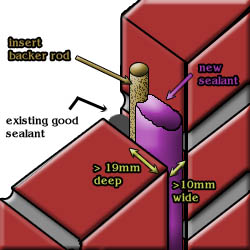

A new sealant should then be placed in the clean joint. All joints should be properly primed before the new sealant material is applied. A backer rope material should be placed in all joints deeper than 3/4 in. (19 mm) or wider than 3/8 in. (10 mm).

The composition of the grout or adhesive should be known when carrying out patch repair or re-grouting of joints to ensure that the repaired works can perform as it was originally designed for. For example, using inappropriate materials for re-grouting might lead to inability of the joint to accommodate movement, which might result in other defects such as cracking to surface.

Identifying the type and colour of the original grout poses a problem (above figure) as the grout changes colour over their useful life. Even if it is possible to correctly identify the grout, there is no guarantee the new grout will match perfectly; it may not even match at all after it is installed and allowed to cure and dry out.

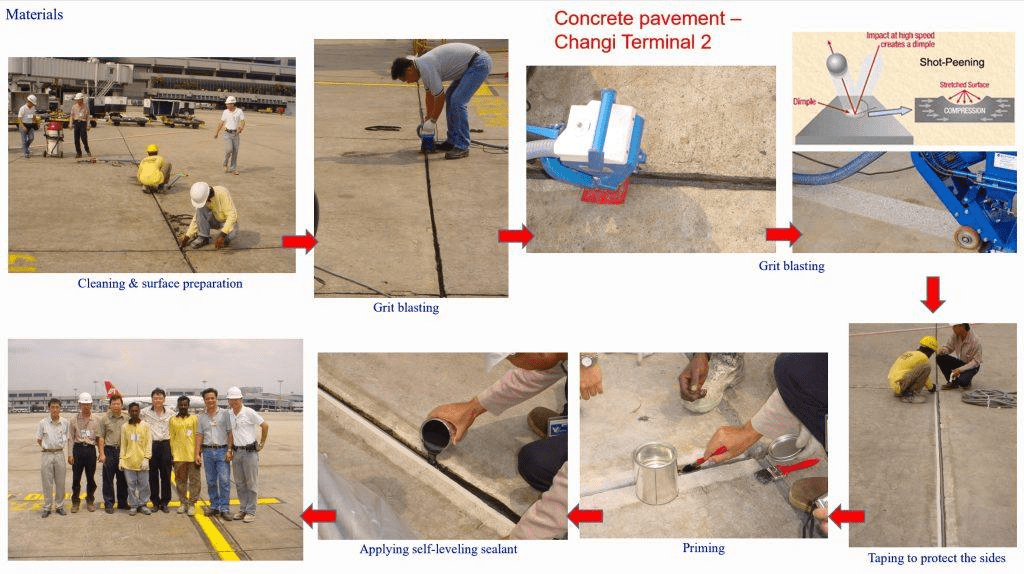

Clean the surface using wire brush, high pressure water jet, grit blasting etc. according to the condition.

Apply tape to protect the adjacent surface: