Case 1

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Cause of Defects

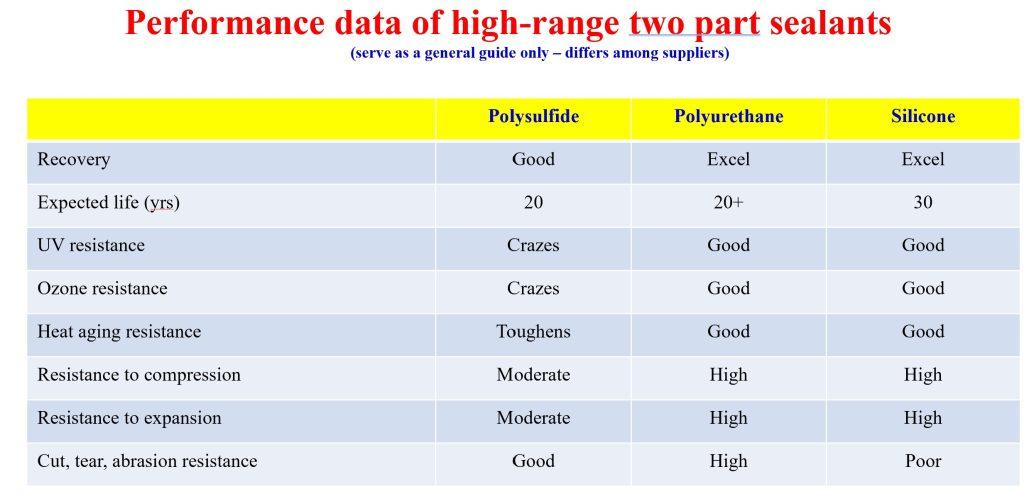

The durability of high-performance sealants can be high if properly selected, installed and maintained:

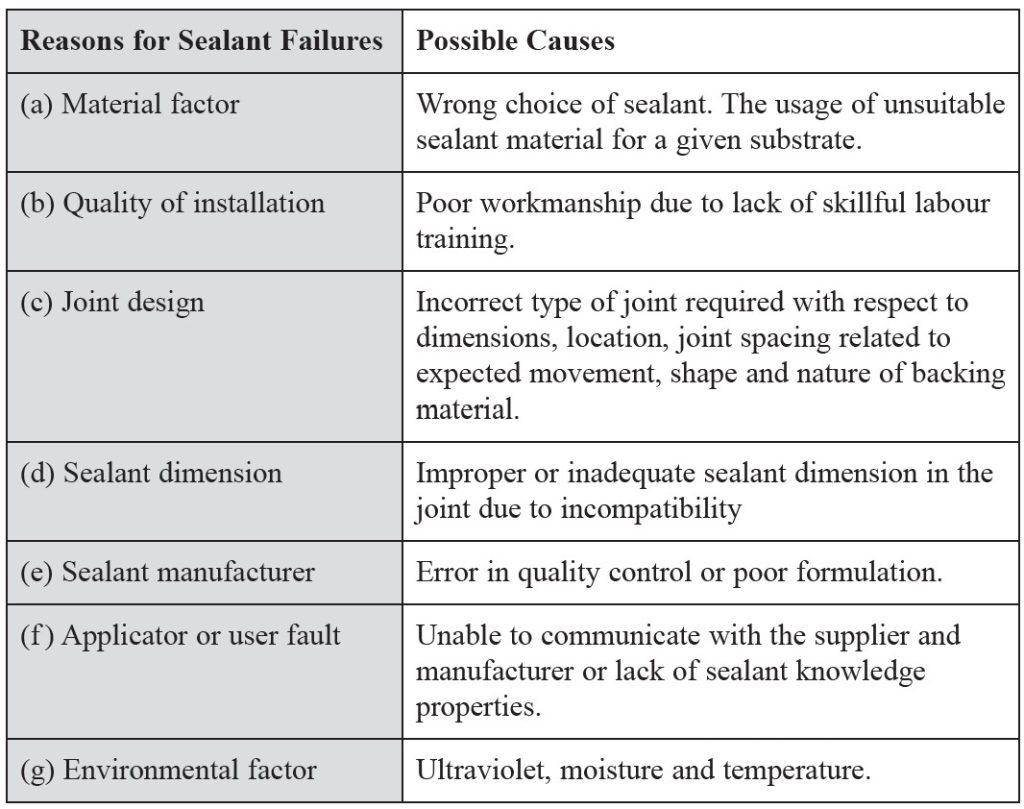

The causes of sealant failures depend on the type of sealant used and its installation and in-service conditions. Sealants as a material can fail due to age and weather exposure. This type of failure is often characterised by discolouration, crazing and stiffening of the sealant surfaces, and is the result of the individual or combined effects of solvent evaporation, ozone attack, migration of plasticisers, ultraviolet radiation, etc. Failure can also occur if there is a large joint movement before the seal is fully cured. In

other cases, sealant failures occur because the sealants were required to take cyclic movement beyond their limits.

Solar and clear night radiation produce extremes surface temperature which can cause external surfaces and surface finishes to crack, craze, delaminate and bulge. In additional, prolonged exposure to sunlight degrades organic-based sealants and gaskets, which then lose their ability to accommodate movement.

- Hardening of the sealant leads to the formation of cracks and crazing. This is brought about by the loss of solvent or plasticisers and by the action of ultraviolet radiation and ozone. Hence the sealant will be more prone to cracking under joint movement.

- Long term exposure to moist conditions. Moisture in the form of rain, dew, high humidity (conditions present in Singapore’s harsh tropical environment) may attack sealants. The hydrolysis of the polymer chemically produces hydroxyl radicals in the presence of sunlight. The product is detrimental to the structure of sealants and may result in leaching of plasticisers and stabilisers.

- The crazing effect is probably caused by the effect of environmental condition in degradation of the sealant. For example, ultra-violet radiation from the sun or ozone causes the organic sealant surface to harden, making it less flexible than the bulk of the sealant below. Hardening can also be caused by loss of solvent and plasticizers.

- The sealant joint flushed with the surface of the panel will also accelerate the degradation because the sealant is directly exposed to the environment. Outdoor installations of sealants are fully exposed to sun and rain, leading to high cyclical change in temperatures. In the tropics, air temperature can reach as high as 45°C. Changes in temperature dramatically alter the properties of the material. High temperatures may change the structure of the material or cause it to melt through random chain scission. For buildings in normal use, the following temperature ranges shall be considered:

External surface temperature: Light colour: +20°C to +60°C

Dark colour: + 20°C to +90°C.

- Chemically polluted environment.

Consequences

Cracks form within the sealant will allow water and air to penetrate behind the cladding and allow moisture to build up. Failure for the moisture to escape may lead to water seepage through the backing wall and damage interior furnishings and decorations. Sealant failures may result in high energy costs, bad quality and human discomfort. In addition, premature sealant failures require high replacement costs.

See Section 4.9.4 of Reference [2] for more details.

See also: Material Manual > Facade > Cladding > Jointing Materials > Sealants