Case 1

- Introduction

- Causes of Defects

- Good Practices

- Standards

- Maintenance and Diagnostics

- Remedial

- Similar Cases

- References

Maintenance and Diagnostics

Adopt ASTM C1193-16 or equivalent to identify areas with remedial sealant repair or maintenance work, as multi-storey structures require a periodic façade inspection at an interval of about 5 years. Replace failed sealants immediately in accordance with ASTM C1401-14, BS EN 13022-1 or equivalent. Test suspected failure of waterproofing using ASTM C1521-19, BS EN 15651-1 or equivalent. Use ASTM C1487-19 or equivalent for remedial work for glazing sealant.

Diagnostics of Defect (see also NDT)

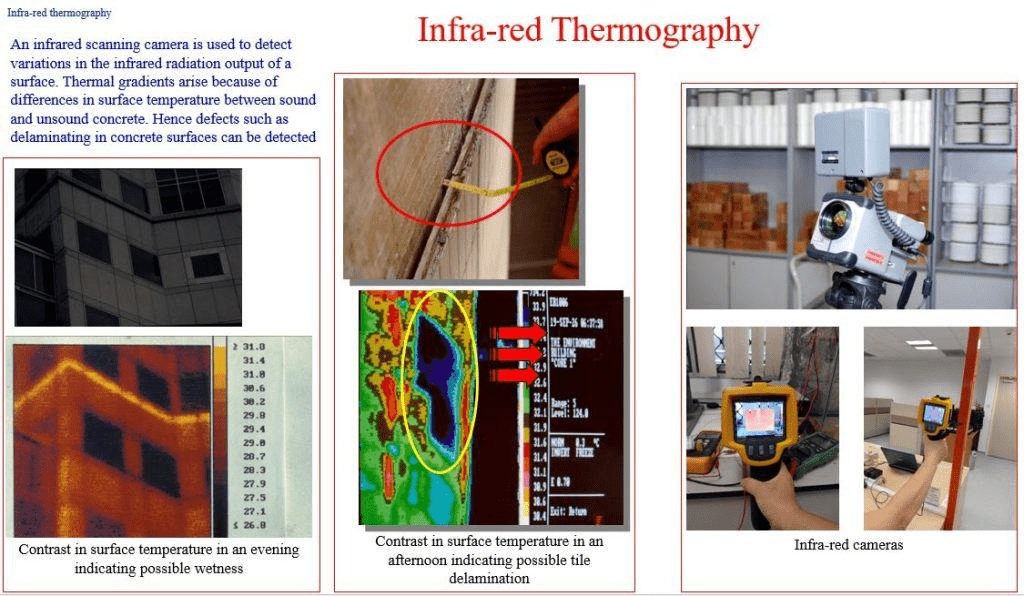

Thermography can be used to identify the position of cracks. A range of crack widths, representing mechanical damage, has been induced under controlled laboratory conditions. The method is based on the characteristics of heat flow phenomenon, in a conductive medium of specific geometry, which is intended to model predetermined boundary conditions.

Elastic recovery meter

Sealant deterioration can be determined by the use of Elastic Recovery Meter (INERT).