TiO2 Coating

Remedial

Use reliable sealants

Used of proven and reliable sealant brand47.

Decrease particle size of coating

A thorough investigation of the particle size and size distribution determined that the average TiC particle size is 4.5 nm and 2.2 nm in coatings 100V80 and 100V110, respectively48.

Besides the change in fracture toughness, the change in TiC particle size and columnar structure between coating 100V80 and 100V110 brings about a considerable improvement in the coating tribological properties. Furthermore, the decrease in Young’s modulus from coating 100V80 to 100V110 is beneficial for the coating adhesion, as the adhesive critical load increases from coating 100V80 to 100V110. Also in this case, a lower Young’s modulus permits to redistribute the applied load over a larger area, increasing the load bearing capability of the coating48.

Using Alkaline cleaning agent for stubborn stains

Only if the stains are unable to be removed, then they should use mild alkaline cleaning agent to remove the stains on the substrates. Usage of a stronger cleaning agent will result in damage to photocatalytic coating47.

Replacing and reapplying photocatalytic coating

Replacement of photocatalytic coating will take place immediately if defects are being identified, instead of setting a specific period for replacement of coating47. Reapplication should be initiated after two (2) years from the application of Topcoat, to ensure that the TiO2 layer remains effective46.

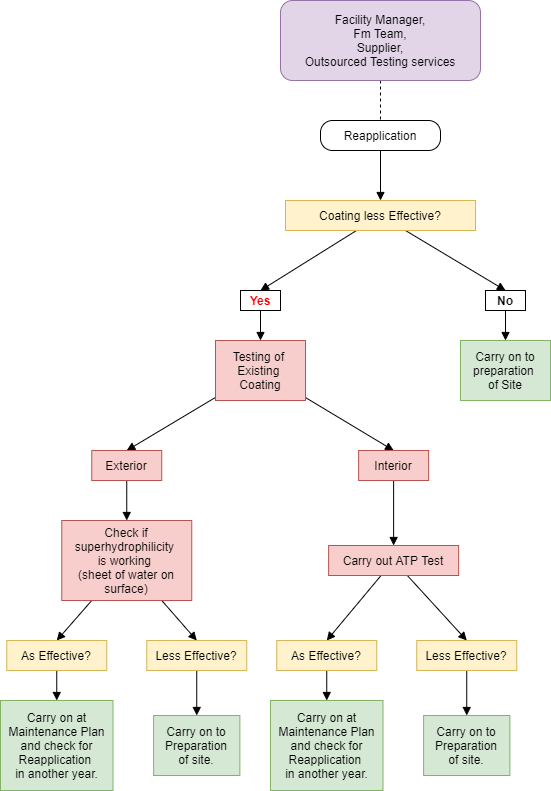

Figure 19 Reapplication Process